Industrial Plastics Shredders: Solutions for Recycling Plastics

Plastics Recycling Machines - Plastic Shredders, Plastic Granulators, Plastic Grinders, & Purging Grinders

If you’re looking for plastic recycling machines for processing large quantities of plastics, you’re at the right place. Whether you’re interested in a plastic shredder, plastic grinder, plastic granulator, purgings grinder or plastic scrap shredder, Vecoplan delivers the absolute best plastics size reduction machinery – period. We make that statement based on 50 years of manufacturing and engineering shredding technologies. We back it with proof from our customers.

Plastics Size Reduction

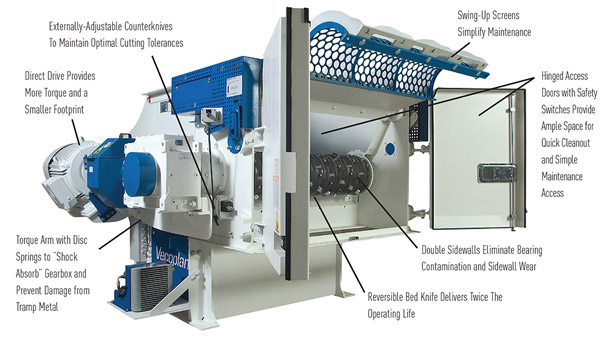

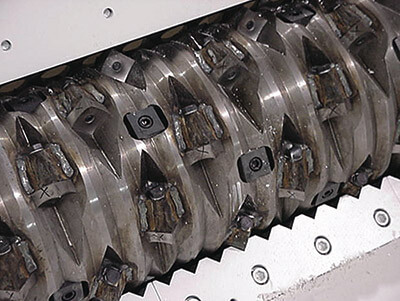

Vecoplan understands plastics processor's goal of plastics size reduction is to convert plastic scrap to a similar size of the virgin processing material. Vecoplan has combined both shredder and granulator features to create a line of plastics shredders that meet virtually all plastics processing challenges including industrial plastic scrap, with over 300 configurations tailored to excel at specific applications.

Plastics Is Versatile - Just Like Our Technology

THE RIGHT SOLUTION FOR EVERY MATERIAL

Different plastics of different shapes and sizes place different demands on the technology: VECOPLAN provides a number of innovative technical solutions from a single source for the necessary processing of plastics for recycling

-

Plastic Granulator & Shredders for Recycling A Variety of High Volume Plastics

Plastic recycling equipment is a broad term that covers many technologies and different types of waste plastic recycling machinery. The types of plastics materials that are being recycled determine the types of recycling machines required such as a plastic granulator. A closed-loop plastics recycling system, or one in which scrap material is taken from a processing line, in a factory manufacturing a single product from one resin type and in one color, can be quite simple. Scrap is simply removed from the line, fed into a shredder, grinder or granulator and reduced to the appropriate size, then conveyed back to the start of the production line, where it is reintroduced as is, or more often blended with virgin resins prior to being reintroduced to the production process.

Learn More Equipment -

Film & Fiber

The FF Series of film and fiber shredders from Vecoplan, the worlds leading manufacturer of film shredding equipment, is the only equipment able to provide Vecoplan’s patented SureCut™ Cutting System. This revolutionary design eliminates the problems encountered with conventional film grinders, fiber grinders, and other types of film recycling equipment including other traditional film and fiber shredding machinery. The SureCut™ system features a specialized cutting geometry that prevents self-feeding and rotor wrapping problems, while delivering precise cut lengths and high bulk densities. SureCut™, incorporated into all of Vecoplan’s FF Series of shredders for film and fiber, is an integral part of many successful film resin reclaim systems in operation today.

Learn More Equipment -

Purgings

Reclamation of plastic resin calls for sophisticated processing, and processing heavy plastic purgings calls for a shredding solution that is tough and reliable. Our resin reclaim systems are designed for high flow throughput with large volumes to meet the highest quality criteria. Vecoplan solutions are highly cost effective for shredding plastic purgings in order to reclaim their resins.

Learn More Equipment -

Pipe

Vecoplan offers several solutions for the processing of plastic pipe (HDPE, PVC, PP), including Vecoplan vertical feed single-shaft shredders and horizontal shredders for long pipe sections. In fact, over half of the top 50 pipe, profile, and tubing extruders use Vecoplan recycling equipment.

Learn More Equipment -

Plastic Container Recycling

Plastic bottles, buckets, barrels, drums, IBCs (intermediate bulk containers), totes andtanks are all popular types of reusable containers. But, at some point, all are damaged, contaminated, or simply wear-out. Once they have reached end of life, their value lies in recycling.The first step in recycling is size reduction, and that’s Vecoplan’s area of expertise.

Learn More Equipment -

Lineal Scrap Recycling

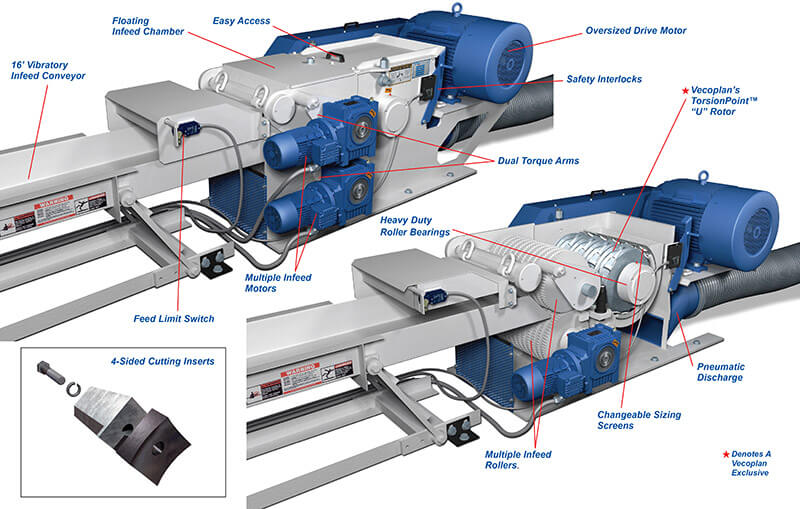

Vecoplan horizontal shredders are fed by 16’ vibratory conveyors designed specifically to move strips, moldings, siding, profiles, composite lumber, pipe, or any long waste. Lineal scrap is pulled from the conveyor and into the machine by both top and bottom feed rollers. A dedicated motor drives each roller. Dual feed rollers deliver aggressive positive feeding and at the same time provide added safety by minimizing material bouncing or flopping common to long scrap. Once inside the cutting chamber, material is processed in much the same way as in our vertical shredders. After material is cut between the teeth on the machine’s rotor and the serrated teeth of the fixed counter knife it exits through a sizing screen.

Learn More Equipment -

Bottles

Machinery used in the process of recycling plastic bottles is one example of a Vecoplan shredder application. Sometimes referred to as PET bottle shredders and sometimes as PET bottle grinders, Vecoplan’s plastics shredding machinery is the ideal solution for plastic container recycling of all types. In addition to PET, plastic recycling machines used in plastic waste recycling need to be able to reclaim plastic scrap such as ABS, Acetals, Acrylics, Engineered Thermoplastics, Mixed Thermoplastics, HDPE, LDPE, Nylon, PC, Poloyolefins, PP, PS, PVC, and others. Simply put – Vecoplan’s plastic shredding machines are successfully used in the plastic recycling process for all types plastic scrap recycling!

Learn More Equipment -

Carpet

An integral part of a wide range of film and fiber waste recycling systems in operation today, Vecoplan’s FF series is a mainstay in the carpet recycling process. While FF denotes machines in this series as a film and fiber shredder, those involved in processing carpet waste simply call them carpet shredders! Recognized as the preferred machinery for carpet size reduction, Vecoplan’s carpet shredding equipment is used in systems designed to reclaim and reuse resins and to recycle carpet waste as an alternative fuel source.

Learn More Equipment -

Dunnage

Molded plastic dunnage is an extremely cost-efficient solution for product protection during shipment, storage, and handling. Designed to fit the exact contour of a given product, plastic dunnage provides maximum product protection - but it is still considered as scrap once the product reaches its final destination.

Learn More Equipment