Vecoplan Solutions For Waste Processing & Waste Recovery Systems

Waste Recovery Systems, Single Stream Recycling Equipment, Biofuels Equipment

Commercial waste - Bulky waste and packaging waste

Production waste - Mixed building and demolition waste

Waste avoidance, conservation of resources and efficient use of recyclable materials are among the most urgent challenges and tasks of our time. The importance of environmental awareness and sustainability is increasing on a daily basis. Our company has been successfully tackling these challenges for more than 40 years, and today we are a leading partner in the international wood and recycling business, with numerous subsidiaries and sales offices worldwide. Learn more about turning waste into a valuable resource.

Waste-to-Energy Concepts To Suit Every Plant Size

The Right Solution For Any Waste Process

-

Municipal Solid Waste (MSW)

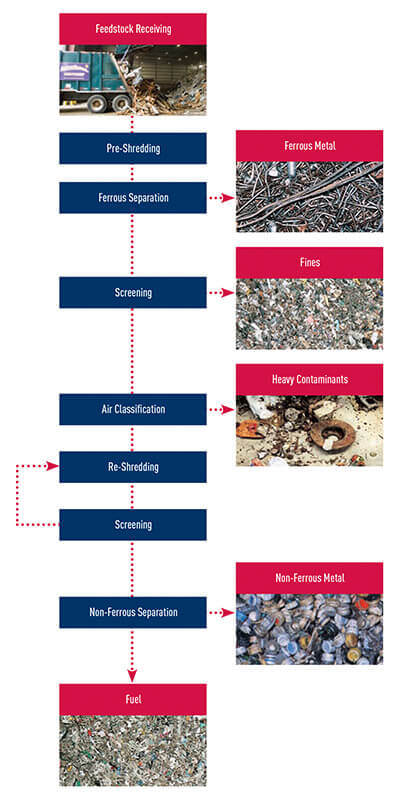

Refuse derived fuel (RDF) is a broad term that covers a range of fuel types, made from a variety of different types of refuse or waste. Commercial, post-industrial and post-consumer waste can all be converted to fuels. These include boiler fuel, pelletized fuel, syngas, cellulosic ethanol, biodiesel, and other second-generation liquid transportation fuels. Vecoplan is experienced with all types of refuse and the various types of fuels they are converted to.

Learn More Equipment -

Medical Waste

Vecoplan is a leader in medical waste shredding equipment and shred technology. Our shredding machinery is an integral part of a superior medical waste treatment system that will help provide the best medical waste management solution.

Shredding medical waste in preparation for landfill disposal is a critical part of medical waste processing. Medical waste requires shredding equipment specifically designed to shred medical waste to an unrecognizable consistency to be acceptable in most landfills. In particular, the shredding of "sharps" has proven to be a challenge for many shredders - but Vecoplan medical waste shredders can process sharps to an unreconizable state with ease - as well as bandages, gowns and other hospital waste.

Learn More Equipment